Things You Will Learn

Learn about a range of different hydraulic circuit designs. This section will show you some of the standard circuits used to control hydraulic systems.

Exploring circuit design options and consequences

Learn about a range of different circuit design approaches and understand when and why they are used.

This section should help you to identify the different circuit designs and understand why they have been used in a particular way. Or if you have a particular performance issue it should help identify what features are required to provide the best performance.

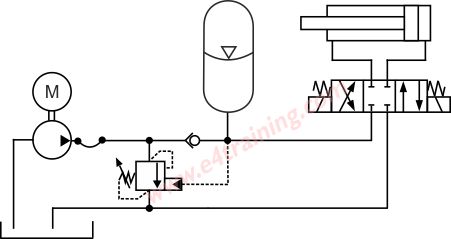

HC01 - Supply Circuit Examples Training

HC02 - Safety Circuit Examples Training

HC03 - Circuit Load Examples Training

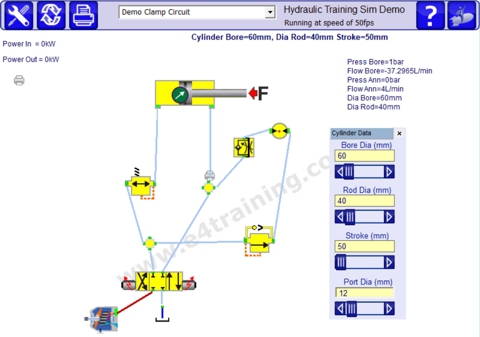

HC09 - Hydraulic Circuit Simulation Software

Experiment with a range of hydraulic circuit layout. This simulation program allows you to select from different hydraulic circuits and test how they work. You can add your own load and performance values to understand how your own systems will work. You can even build and test your own circuits. We will be adding lots of example training circuits within this software.

- Test a range hydraulic circuits

- Add real operating values to test actual circuits

- Design and test your own circuits

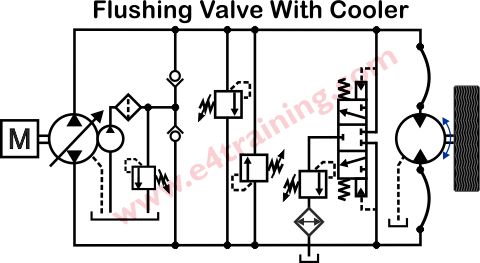

HC06 - Hydrostatic Closed Circuit Drive System Designs

Learn the basic principles of closed circuit, hydrostatic drive system design. Content covers:

- Charge pumps

- Braking relief valves

- Flushing valves

- Holding brakes

- Low-Speed/high torque motors

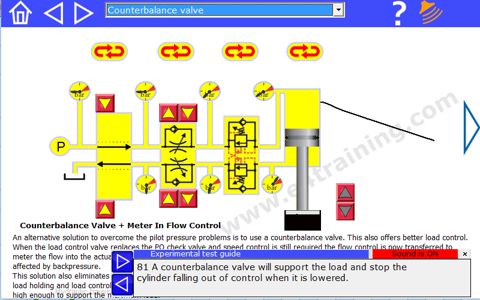

HC07 - Hydraulic Load Control Fundamentals

Examine a range of load control circuits to understand some of the problems and pitfalls of moving loads with hydraulics. We consider each circuit and discuss the pressure balances that make them work. We show you how to experiment with our valve simulations to explore the circuits and better understand how they work.

Please note that the fluid stiffness values have been reduced in our simulation to better demonstrate the potential problems when using different load control circuits. This can be seen in delays when lifting the cylinder and oscillations when it's stopped suddenly. The issues do appear in actual systems but are only a problem apart for highly dynamic or high accuracy control systems. Examples include:

- Cylinder creep due to spool leakage

- Uncontrolled cylinder dropping

- Meter out or meter out flow control

- Pilot operated check valve load holding

- Instability caused by long pipe lengths

- Back pressure issues

- Externally vented PO check valves

- Counterbalance valve

- Proportional valve with unvented counterbalance

- Vented counterbalance with proportional valve

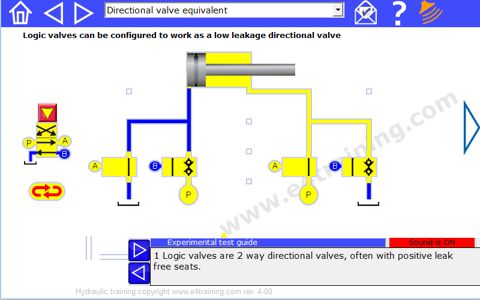

HC08 - Logic Circuit Designs

Learn about a range of logic control circuits to understand how they work and where they may be used. We show you how to experiment with our valve simulations to explore the circuits and better understand how they work. Approaches include:

- Directional valve equivalent

- Isolating slice

- Freewheel crossover valve

- Re-generation slice

- Relief/red. gives proportional control

- Relief valves give +/- accn control

- Free design mode

Applies to the following areas

This module applies to both mobile and industrial applications although much of the more comprehensive control features will only be used on industrial applications. Lower cost power units in the industrial sector are very similar to the simpler mobile power units.

Target Audience

People who are responsible for hydraulic equipment in the following ways:

Managing or purchasing hydraulic equipment.

Maintenance Engineers repairing hydraulic equipment.

Hydraulic equipment designs.

Previous knowledge required

Students are expected to be familiar with:

1. The operation of hydraulic fluid power equipment.

2. Understand hydraulic components and where they are used.

3. Able to read hydraulic circuit and their symbols.